The Easiest Way of Digital Printing - Sublimation & Transfer Printing Fabrics

Sublimation fabric printing is used in various advertising displays and many daily use applications.

The biggest benefits of sublimation fabric printing are its image durability, softness, flexibility, foldability, and washability.

You can find our sublimation fabric varieties suitable for digital printing for flags, satin, display-advertising, backlit-lighting, blockout-darkening, and decoration purposes from here.

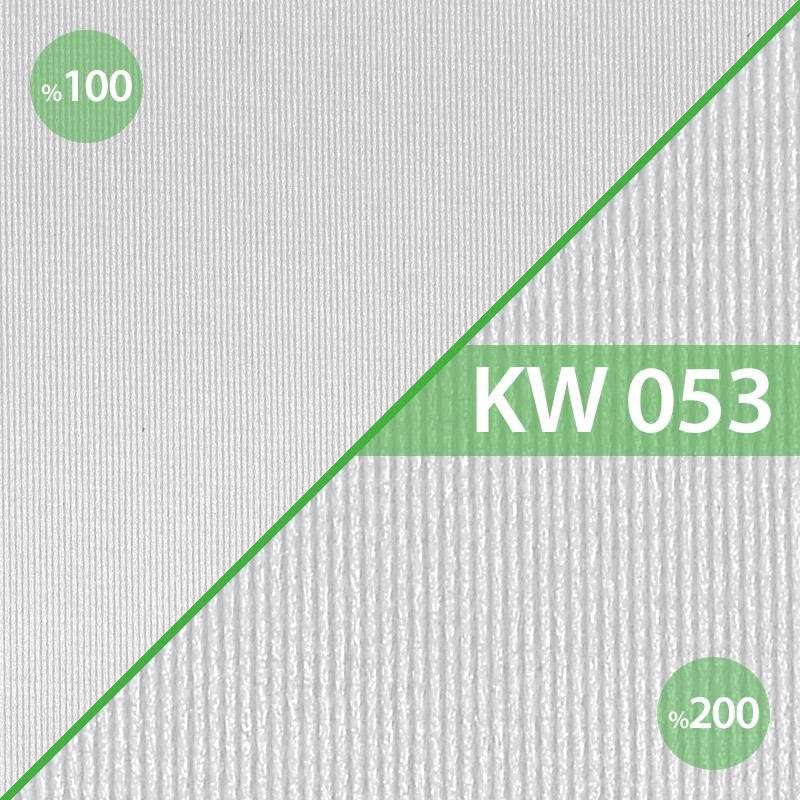

KW 053 SILVER GLOSSY (High Gloss Satin)

Our glossy satin fabric is 100% polyester and is produced suitable for direct sublimation and transfer printing.

The weight of SILVER is 200 grams per m² and its maximum width is 320 cm.

It is a suitable product for applications such as flags/ banners/ indoor decoration (tablecloth, curtain, pillowcase).

Sublimation fabric printing is simpler and faster compared to printing techniques such as screen printing and traditional printing.

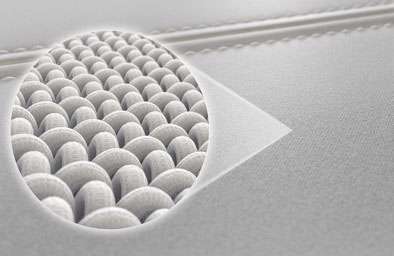

If we touch upon the application stages of sublimation printing, sublimation inks react with heat and pressure to convert the ink into a gas.

When heat is applied, the pores on the fabric surface open and allow the color in gas form to flow into the open pores. As the fabric surface cools, the pores close and trap the ink permanently in the fabric.

Since the ink in gas form fills the pores of the lower layer rather than accumulating on the surface, it allows the emergence of permanent, vivid, and saturated color tones.

If the image and graphics printed on the fabric get dirty, it is possible to wash it in a standard washing machine.

This saves on reprinting costs, providing savings and long-lasting use.

Sublimation printing is divided into two types: transfer and direct (inkjet) printing.

Transfer Printing

First, the ink is printed with the help of a printer on a transfer paper designed to hold the dye.

Then, as a result of the contact between the fabric and the graphic printed on the transfer paper under heat and pressure in a heat press, the ink embedded in the paper is converted into gas and penetrates the fibers of the fabric, resulting in the printing process.

Direct Sublimation Printing

In direct sublimation printing, inks are directly printed on the surface of the fabric, eliminating the need for a transfer paper.

To ensure that the dye penetrates the fabric permanently in the sublimation process, the printed fabric must pass through a heat chamber.

When the temperature reaches 195°C, the inks are embedded in the fabric and fixed permanently.

Before heating, the image seems dull and matte. After the heating process, the chemical reaction that activates the ink with heat results in the graphic on the fabric being dominated by permanent, sharp, and saturated colors.

What Are the Differences Between Transfer and Direct Sublimation Printing?

-

Direct dye printing allows the color to pass through to the back of the fabric by penetrating deeper into the fabric.

When it is expected that the fabric printing for flags and similar products will pass to the back surface, our best-selling product, KW 48 - SUPER GLOSSY, is our most preferred sublimation fabric.

KW 48 is our sublimation fabric made of 100% polyester weaved flag.

It provides superior printing results with a high reflection effect percentage on the back surface of the fabric of your printed design.

It is suitable for direct and transfer sublimation printing and is also used for UV and Latex printing. Its weight (120 g/m²) and maximum width (320 cm) are its features.

-

Transfer dye printing inks sit on the surface of the fabric, allowing the threads to be seen when the fabric is stretched, which is an undesirable situation.

Our ALPHA - KW 034 fabric is a 100% polyester, weaved lightbox fabric.

It is produced for direct sublimation printing.

ALPHA's weight is 240 g/m², and its maximum width is 320 cm.

It provides a clear and saturated print quality in all kinds of stretching and elasticity situations, as ink penetrates directly into the threads.

It is a suitable choice for Backlit/Lightbox/Decoration applications.

What Are the Technical Specifications Sought in Sublimation Fabric Printing?

In general, when the sublimation fabric printing meets the headings such as tear resistance, warp and weft stability, heat chamber - stretching from both lengthwise and crosswise, and ink retention, you can be sure that you have found the fabric you are looking for.

All fabric types we produce at Soletex are produced in accordance with international standards.

The tests we apply during the production stages are listed below.

Fabric Mechanical Tests

-

Tensile Strength

-

Tear Resistance

-

Water Repellency

-

Anti-Bacterial / Antiviral

-

UV Resistance

-

Abrasion Resistance

Fabric Color Fastness Test

-

Light Fastness

-

Rubbing Fastness

-

Washing Fastness

Recycled Products

We use recycled yarns in line with our environmental policy.

Can Direct Sublimation Printing be Sustainable?

Sublimation inks are the most sustainable method in the digital printing sector because they use water-based colors and eliminate the use of paper during the printing process.

KW 005 TOKYO

Our fabric is 100% Polyester, woven,Wall Covering fabric.

It is produced for Direct and Transfer printing.

TOKYO has an weight of 195 gr per m² and a maximum width of 300 cm.

Like water-based paints used on your walls, TOKYO is produced suitable for sublimation ink printing, so you can use it comfortably in your indoor spaces.

Packaging Advantage

When considering the shipping of printed sublimation fabrics, they are preferred in the digital printing sector because they can be folded and offer a much simpler and practical packaging opportunity than other fabric types.It enables to remove, replace, wash and reuse the fabrics repeatedly after they are displayed.

Our Digital Printing Fabrics Suitable for Sublimation and Other Printing Types

Soletex, with its research and development (R&D) studies exceeding 15 years, advanced technology machinery and knowledge accumulation,offers the best solution for the digital printing industry.

Soletex Digital Printing Fabrics

is the supplier that advertisers and marketers around the world rely on for their fabric needs for sublimation and other printing types.

We produce innovative, developing and digital printing compatible fabrics with our quality, wide-format and long-length fabrics. We cover all steps of production from yarn, weaving, coating, cutting and packaging, as well as finishing application, graphics, digital printing and accessory production.

Our product range, produced in line with digital printing technologies, includes flags, satin, display-advertising, backlit-lighting, blockout-darkening, decoration and more.